2020-09-14

Fivetech introduces Smart Pull Handle to innovate the way of fingertip pulling and fastening, which embodies the special performance of elastic knobs to meet the versatility needs of hand-pulled fasteners

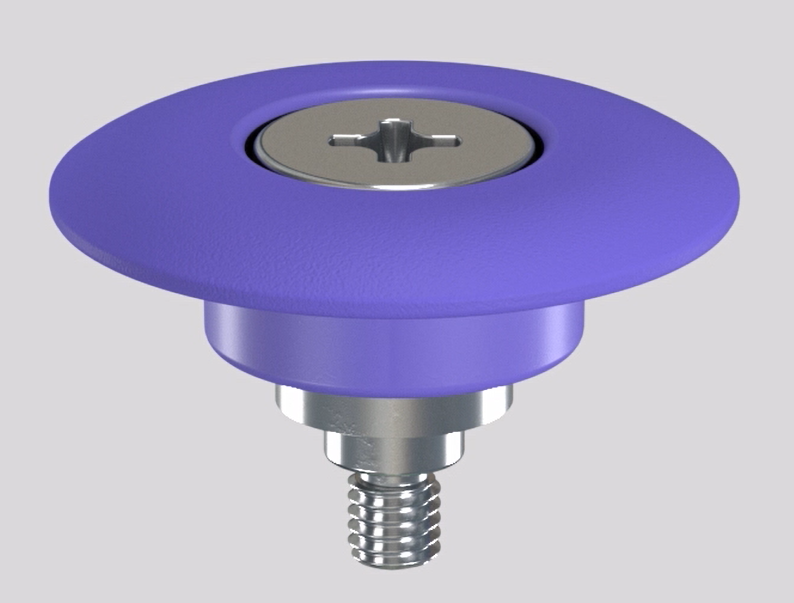

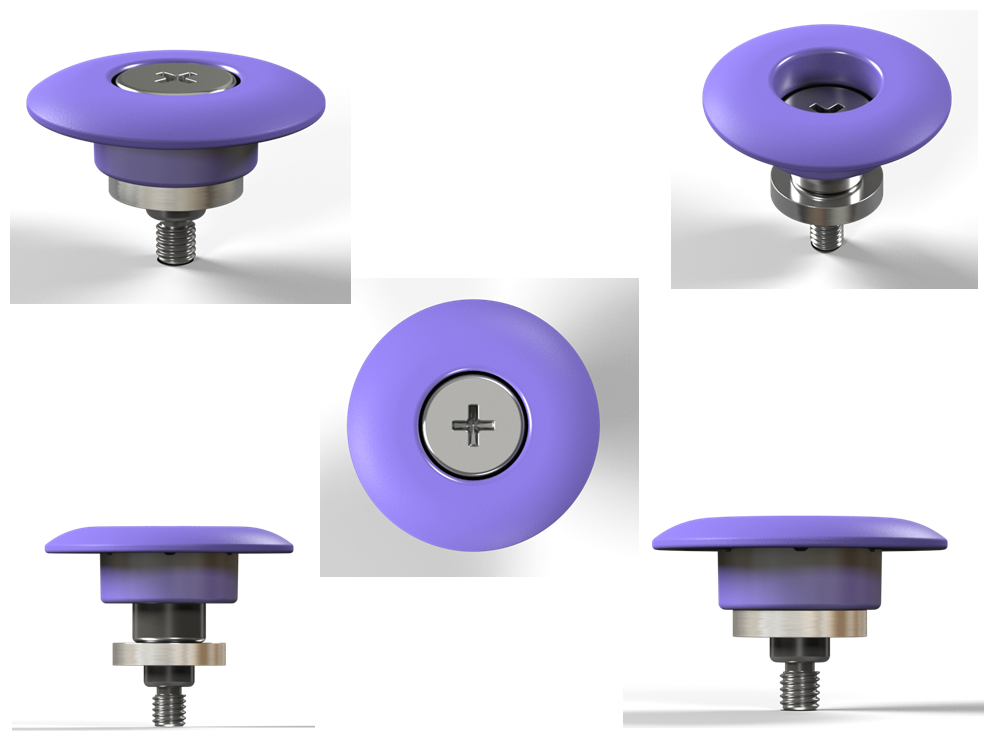

When the head knob design of the fastener is generally round shape like the ordinary design, it is often not suitable for various multi-functional purposes and finger-pull methods, and most of the space height restrictions required to cope with the chassis panel design are usually only as compact and short as possible. Or use of common ordinary hand-tightening screws without much of choices because of their inherent common functionality. However, in order to expand the customer’s response to new demands, the function of easily pulling, extracting and tightening the knob can be designed in the chassis panel with relatively limited space. Especially for the convenience of pulling, Fivetech has introduced a new Smart Pull Handle with a special super-large head type. The Smart Pull Handle is a button fastener product that promotes and enhances the resistance of the tension spring force. Assemble smart handles on the chassis or server drawers that need to pull or pull the chassis.

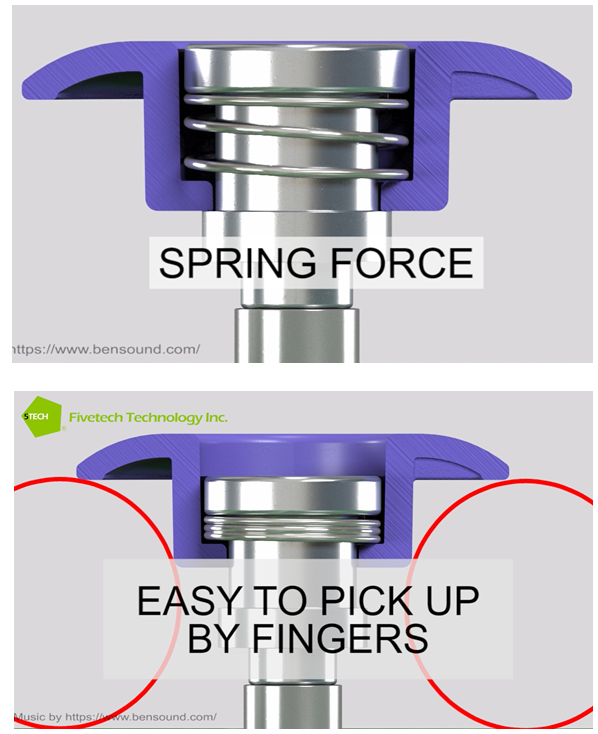

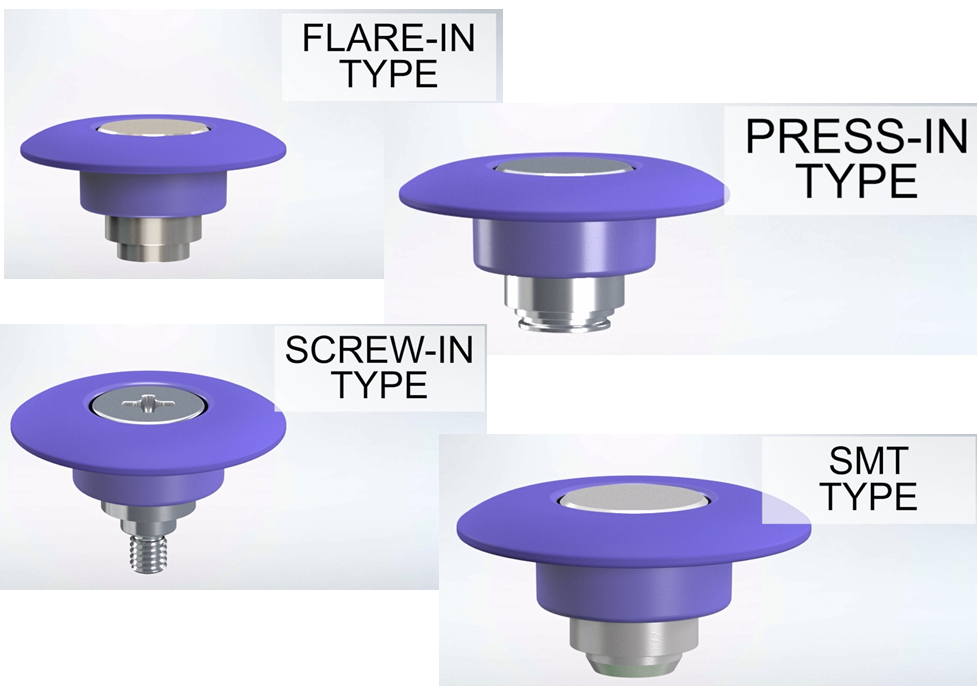

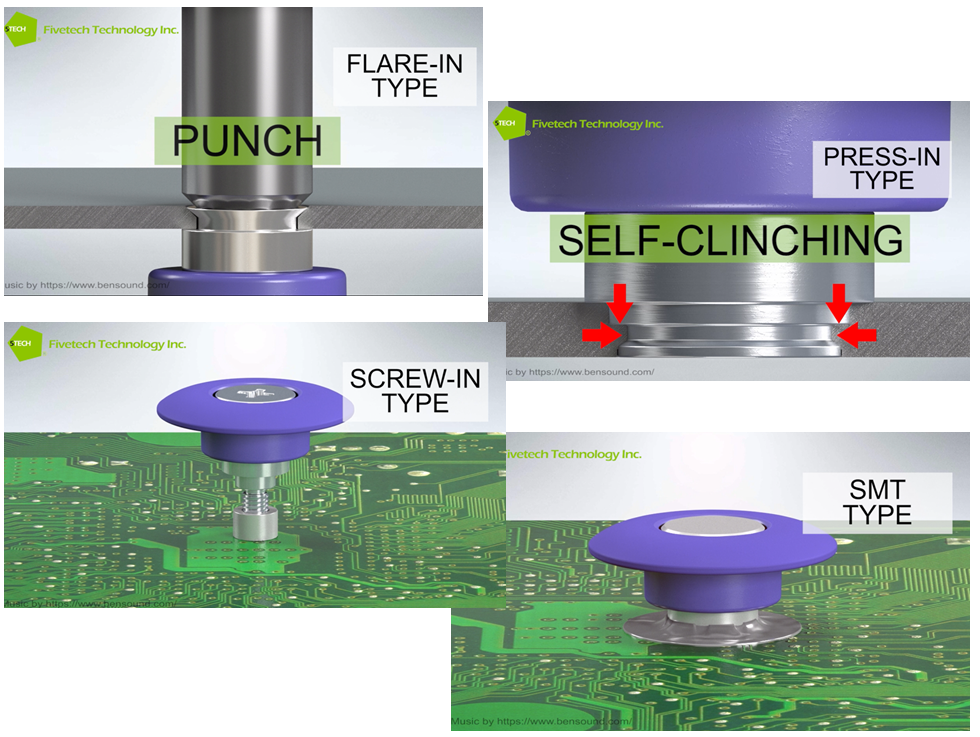

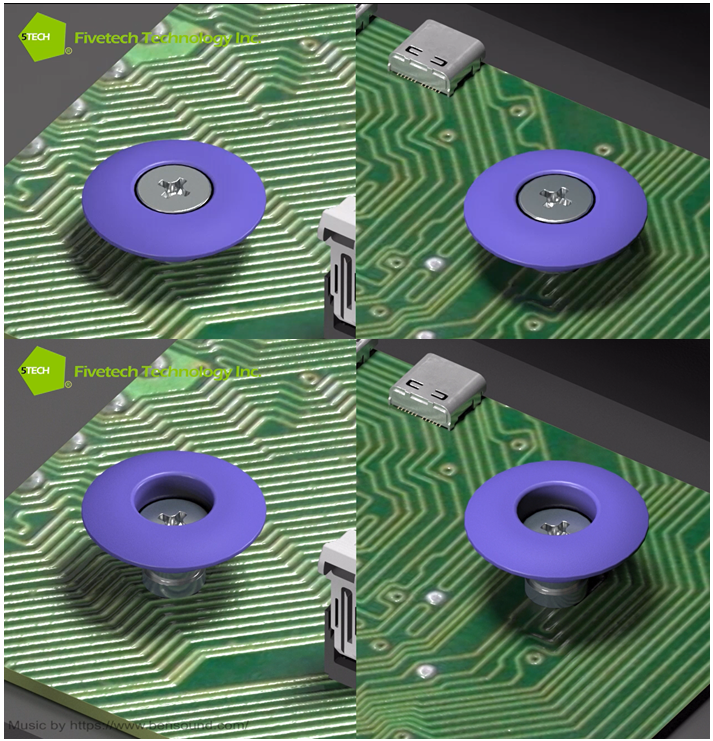

The special handle design of the Smart Pull Handle has an ergonomic handle advantage when pulling. The spring force tightening can ensure that the heavy objects are lifted avoid slipping or falling, and increase the operational stability and convenience. The larger knob UFO design can add extra finger grip on your fingertips, which has the function and advantages of handle satisfaction. It can add extra strong grip at your fingertips, provide powerful handle function and more load capacity. The strong endurance design improves the safety and reliability of the product. The special handle design can provide the ability to handle. The strong endurance design improves the reliability of the product and can manages the plastic color. The handle increases the convenience of operation. The smart handle can provide four different assembly methods: Flare in, Press in, Screw in, SMT.

![]()