2020-07-28

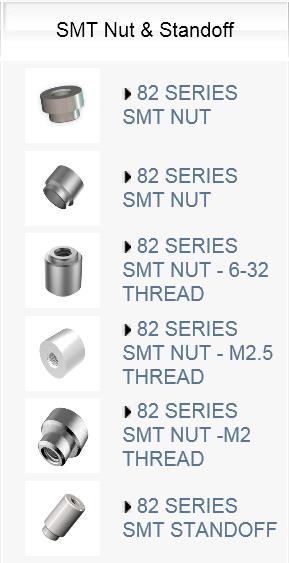

Fivetech SMT Nut 82 series to provide complete range of product line for all thread sizes, gradually replacing the traditional assembly methods. SMT soldering process can excluded the wary of cause of PCB damage by clinching stamping process damage.

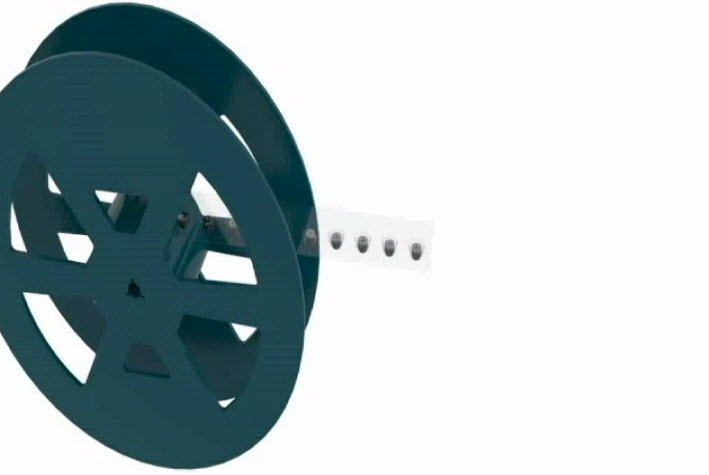

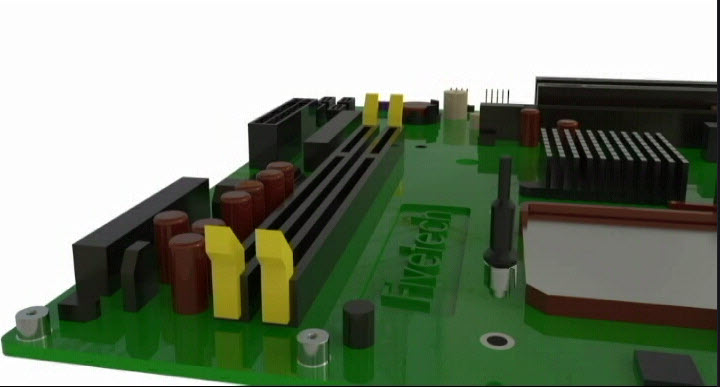

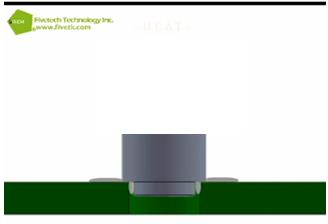

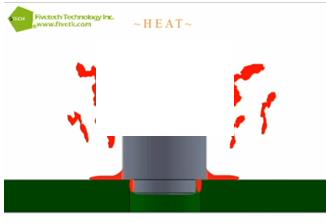

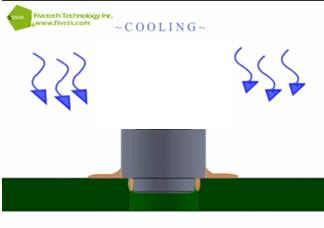

Fivetech 82 series SMT Nut used on PCB has been widely accepted by the market. SMT technology has gradually evolved into a mature technology that has been gradually replacing the traditional assembling through its SMT process, allowing the assembly process to achieve maximum yield, the industry can take advantage of existing SMT production lines, the use of vacuum suction pick SMT Nut from the reel, pick and place onto the tin solder pasted on PCB, through tin heating and cooling process, the heat melt tin, cooling to solid tin to complete SMT Nut assembly process. SMT process can reduce damaged to PCB caused by punch skew placing nut on PCB, this result to often easily damage the board. To progress, SMT process can accurate positioning and results maximum yield.

Another reason customer choose SMT Nut is due to the design of the PCB, due to the demand of no drill hole on PCB. SMT process take advantage of none-perforated PCB design. SMT Nut will be placed directly on the PCB board, the same way to use of tin solder paste parts to fixed on board. Solder paste welding process, ensures the most reliable assembly.

Fivetech SMT Nut 82 series finish on all sizes and models are complete range of product line, providing customized design, multiple choices formality. Fivetech uphold quality control production quality advantage, from design manufacture to material out goods on reel, single production line to ensure quality control. Fivetech SMT Nut carry quality appearance to receive customers well commends and trusted recommendation.

SMT Pick and Place process

SMT Tin solder paste process

![]()