2020-12-03

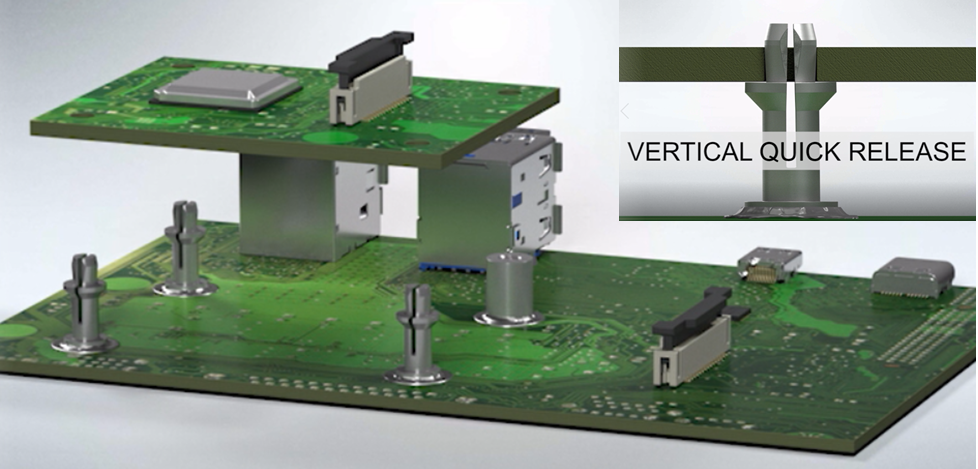

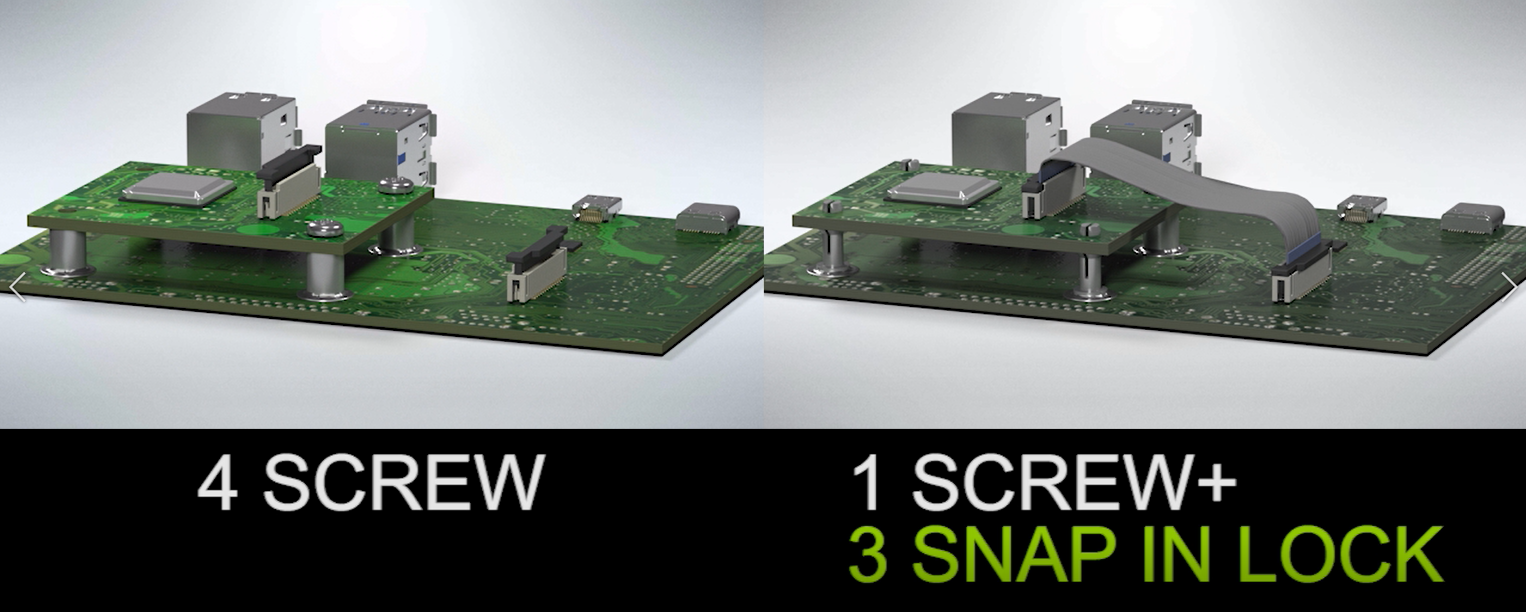

SMT SNAP IN LOCK claw buckle gradually replace traditional screws. PCBs are buckled with vertical through-hole claws to improve assembly time efficiency. SMT surface mount technology ensures the most stable assembly between components and PCBs.

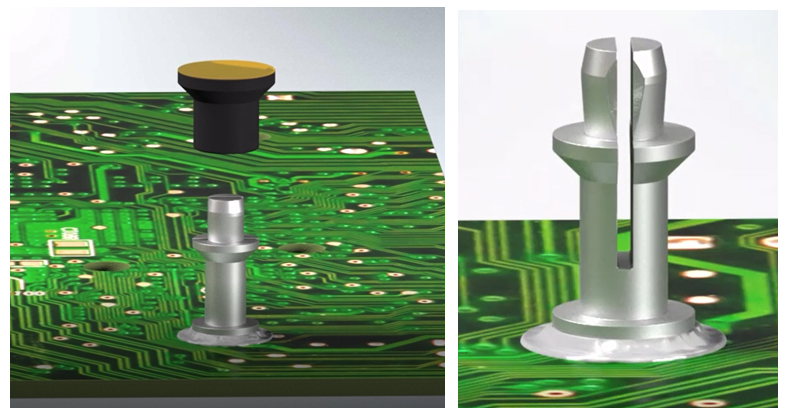

For example, when the traditional pointed locking pin SMT PIN is inserted into the PCB, it will often face product quality instability due to various reasons, such as skew, deviation, loose parts or excessive position, and when fixed and assembled on the PCB, all these Poor quality will cause damage to the PCB or cause more serious cracks or high defect rates such as NG parts, resulting in waste of time and cost. If you change to adopt SMT SNAP IN LOCK claw buckle, when the claw buckle is vertically inserted into the through hole for claw buckle connection, the special claw buckle head design can be used to buckle by the extension force of the claw metal to extend outward The through-hole grooves on both sides can reversely buckle the PCB card, and can be fixed vertically to repeat the claw buckle placement operation process, gradually replacing the traditional screw lock or PIN lock, improving time and cost efficiency. Compared with traditional screws, it saves 90% of assembly time.

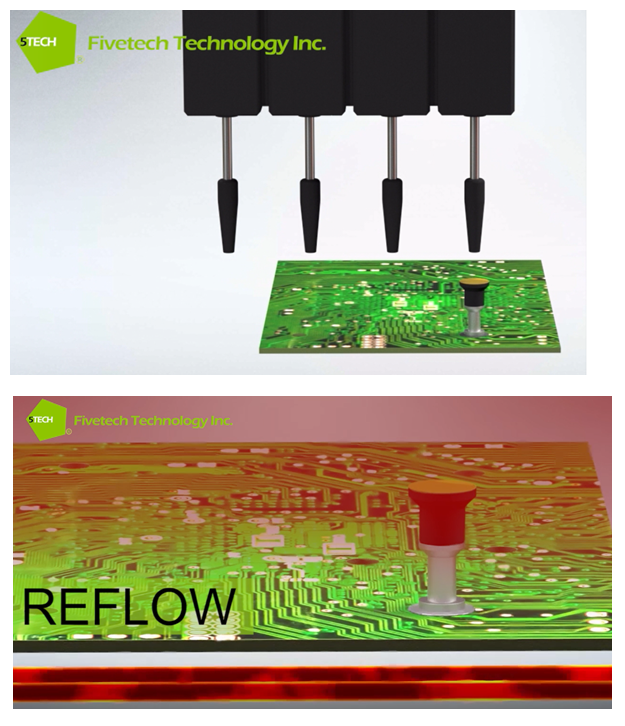

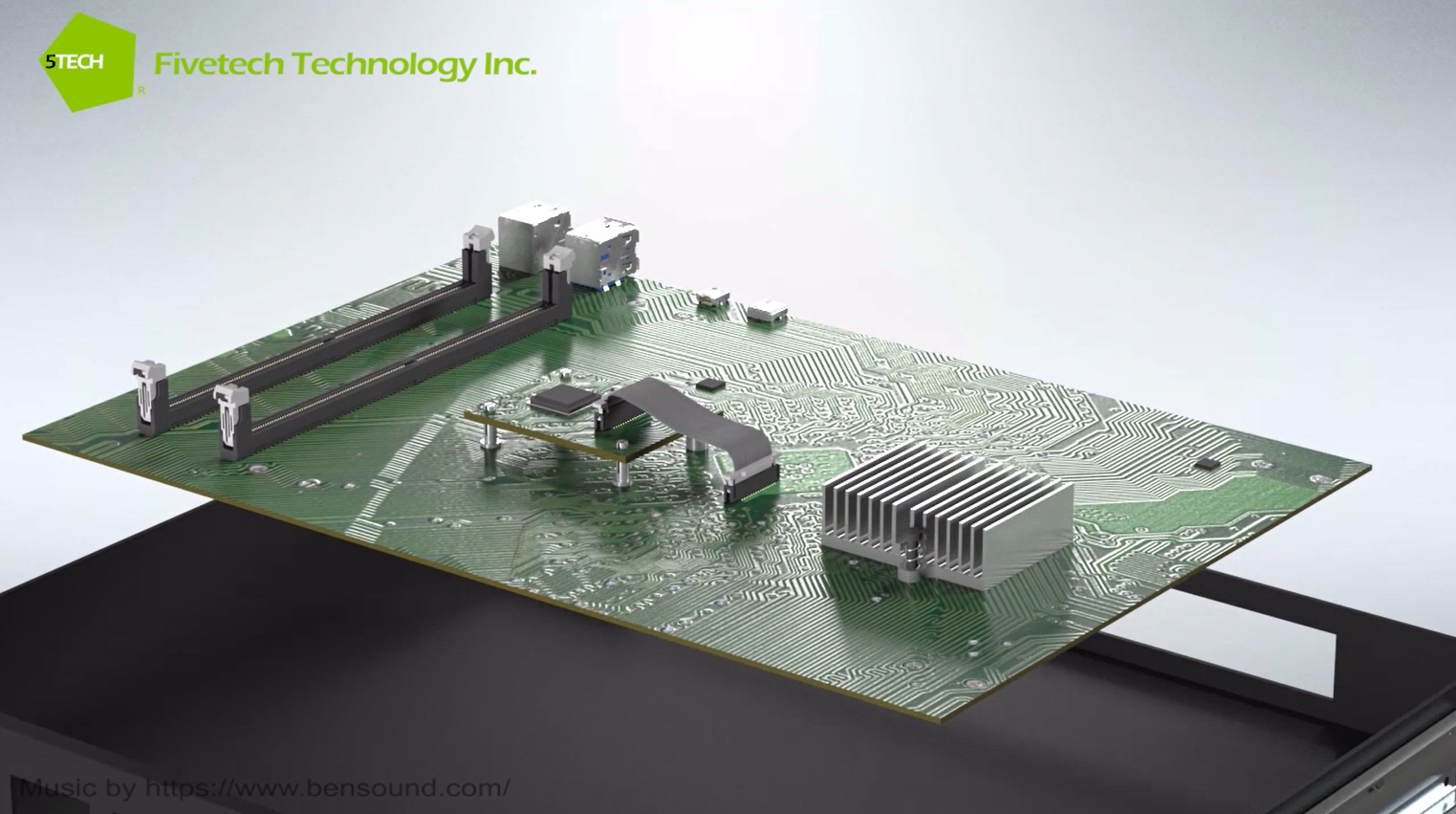

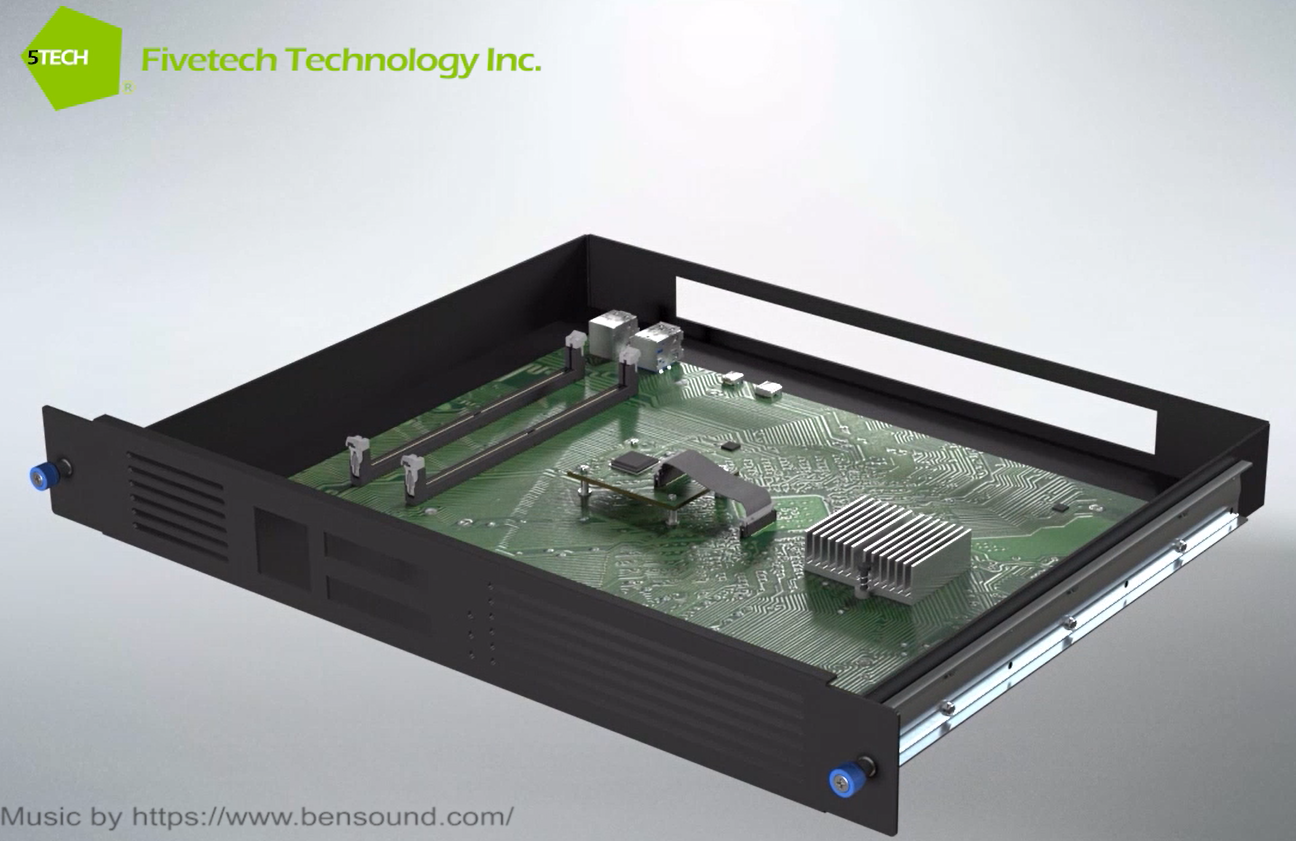

SMT surface mount technology, first insert the claw button to the SMT reel, and then carry out the automatic suction and placement process, suck the claw button of the vacuum nozzle from the reel, and then transfer it onto the PCB, and then pass the SMT uses solder paste technology for soldering. The process is carried out in four steps through heating-immersion-reflow cooling, cooling and solidification into a solid metal template to complete the soldering process and complete the installation. This technology is to cool the liquid solder paste into a solid metal form. The whole process uses SMT automated machines, which will not cause the parts to be loose and skewed, and it can reach a 100% pass rate. The use of SMT fixed claw button technology on PCB is gradually replacing traditional PCB assembly technology.

SMT advantage

* Gradually replace traditional screw lock, which can increase production line output and cost’s consumption

* Replace manual processes to save time and reduce error manufacturing costs

* Automatic mechanical process 100% yield pick and place, fast and accurate positioning

* Solder paste soldering process, liquid metal is cooled into solid metal, SMT ensures the most stable assembly between components and PCB.

* Achieve 100% product quality stability without increasing parts failure

Type of mounting style on PCB application

In addition, in the SMT process, due to the different materials and shapes of the metal parts, in order to more effectively achieve the suction effect of the vacuum tip, it is recommended to use Connect-cap to cover the top groove to maximize the stability of the vacuum, so as to Easily pick up and place in the holes on the PCB. After installation, remove the connection cover.

![]()