2020-12-25

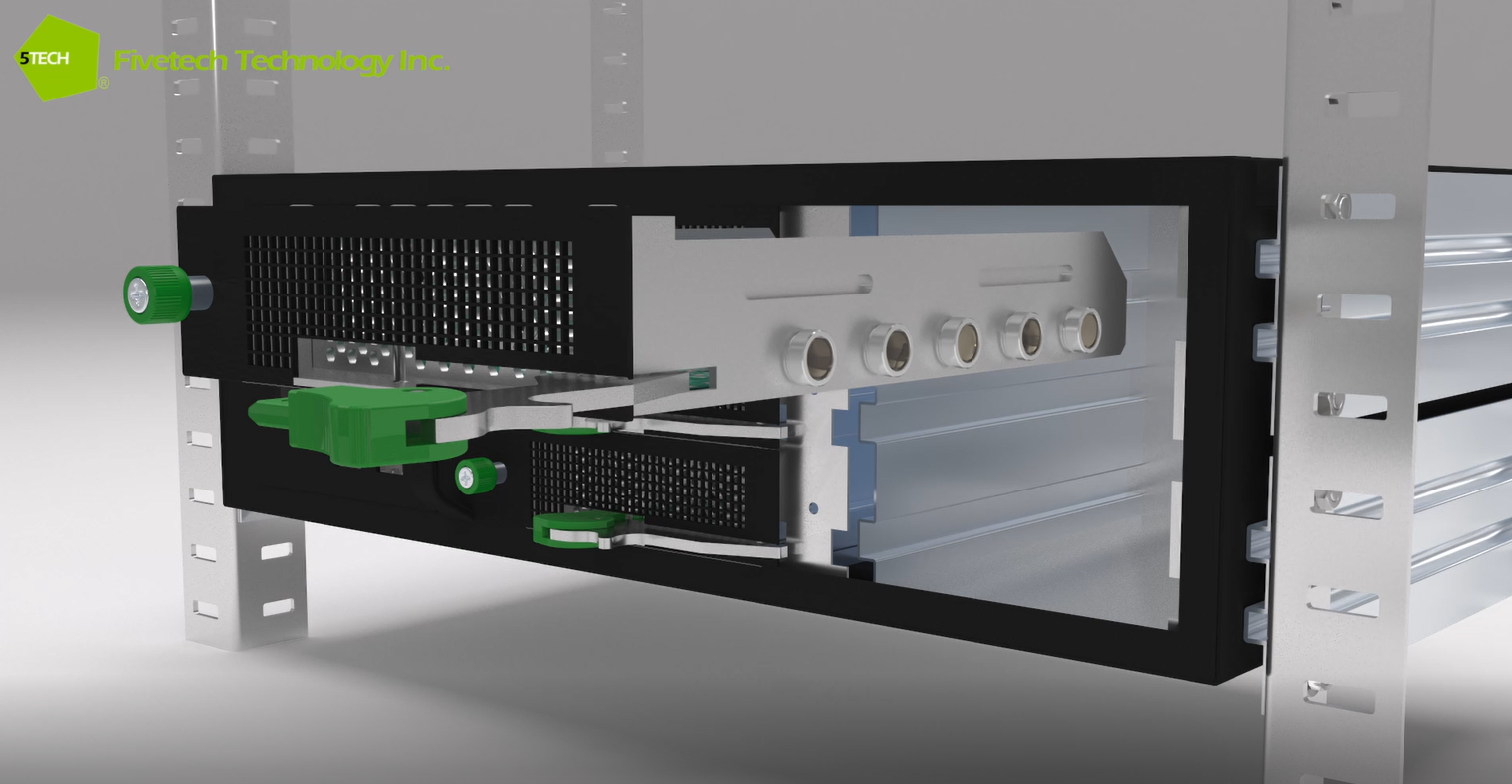

In the cloud data center, the Rotating Ejector is the most complicated and frequently used set of locking tools in the server application. It must be designed to be user friendly and convenient to use and labor-saving to optimize the efficiency of the engineer; the side of the chassis equipped with Slide Roller lateral wheel track, the server tray is treated as a freely sliding wheel car, so that each servo cabinet can reach the highest efficiency.

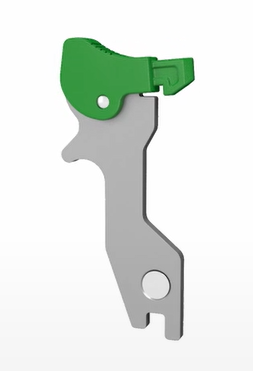

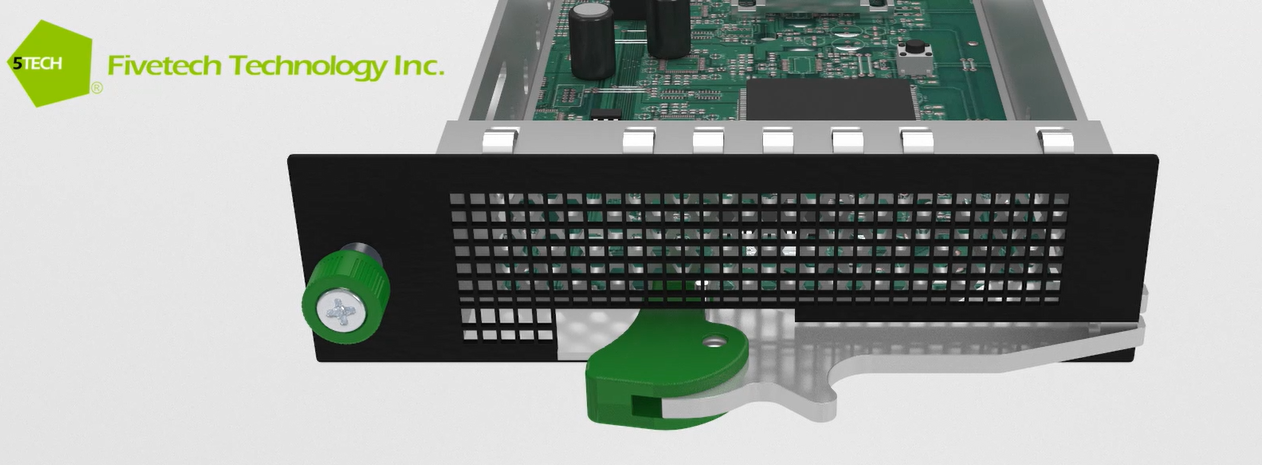

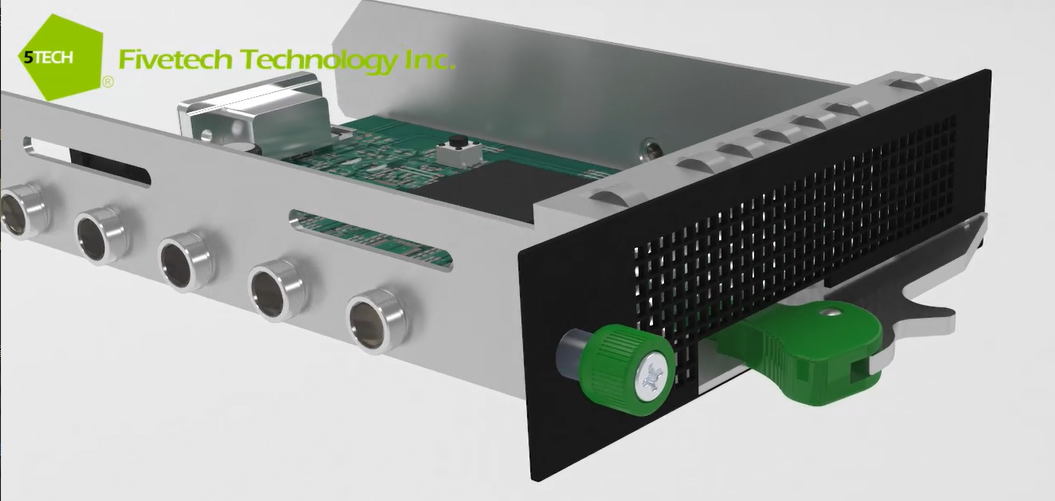

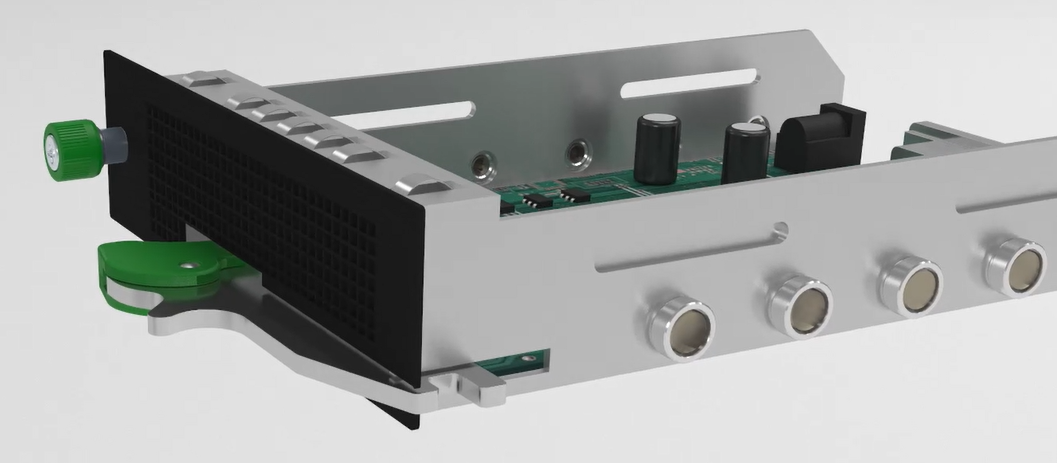

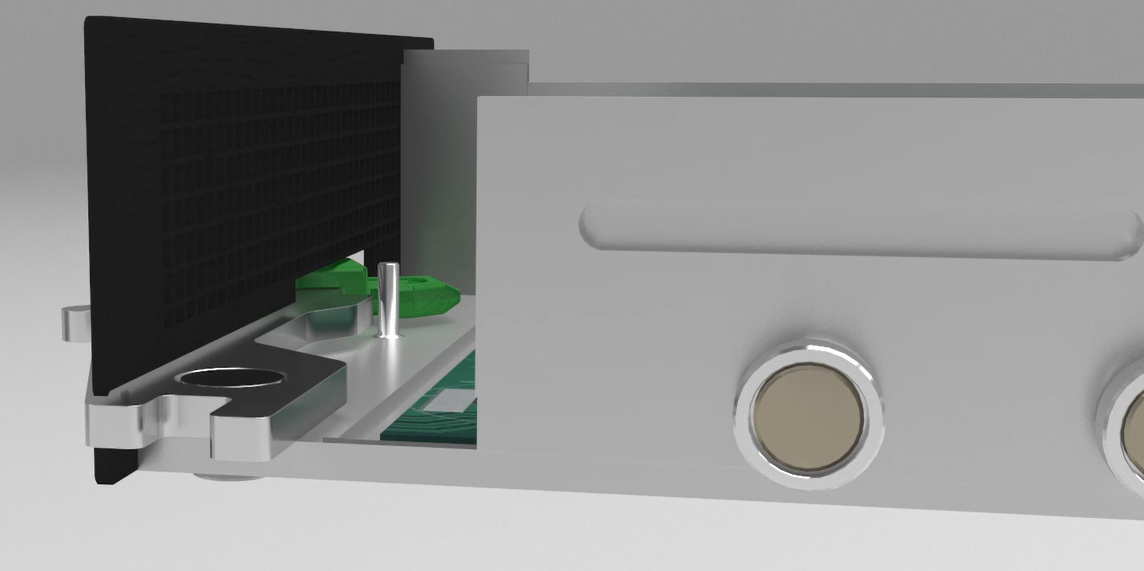

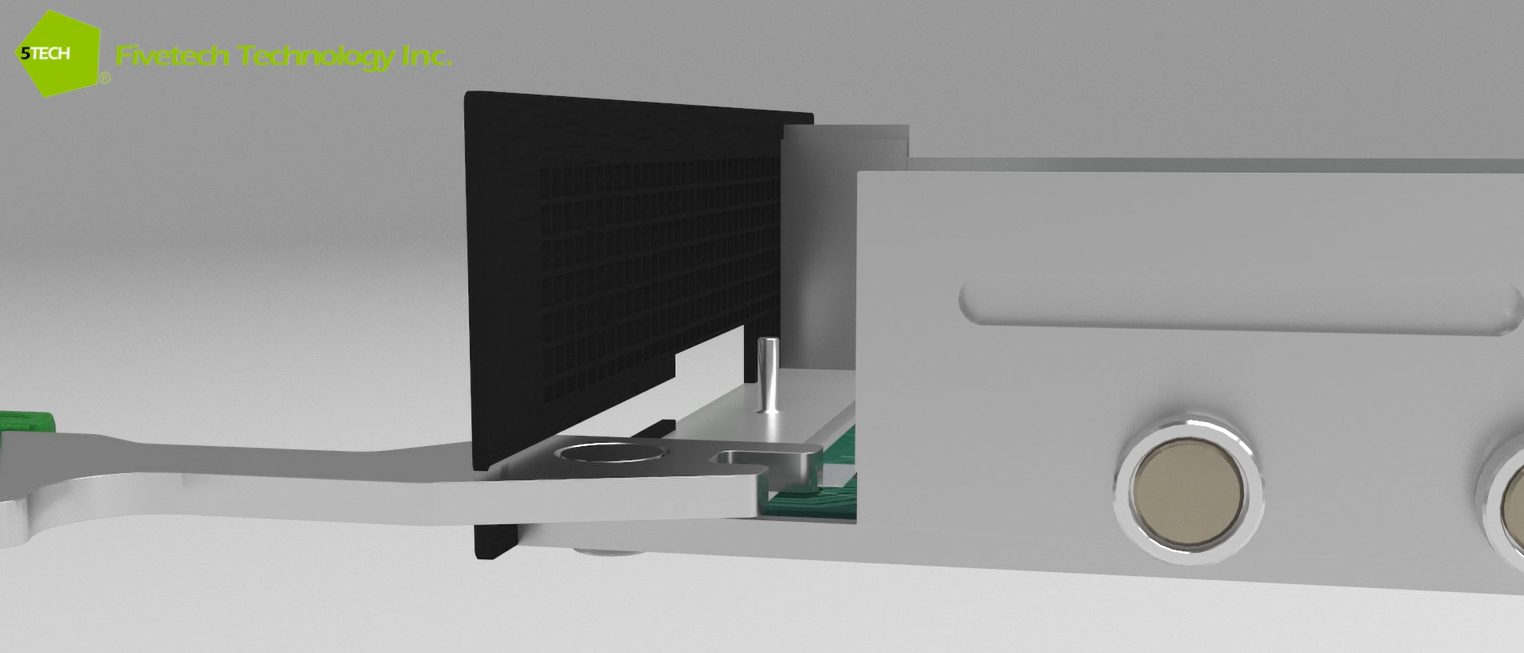

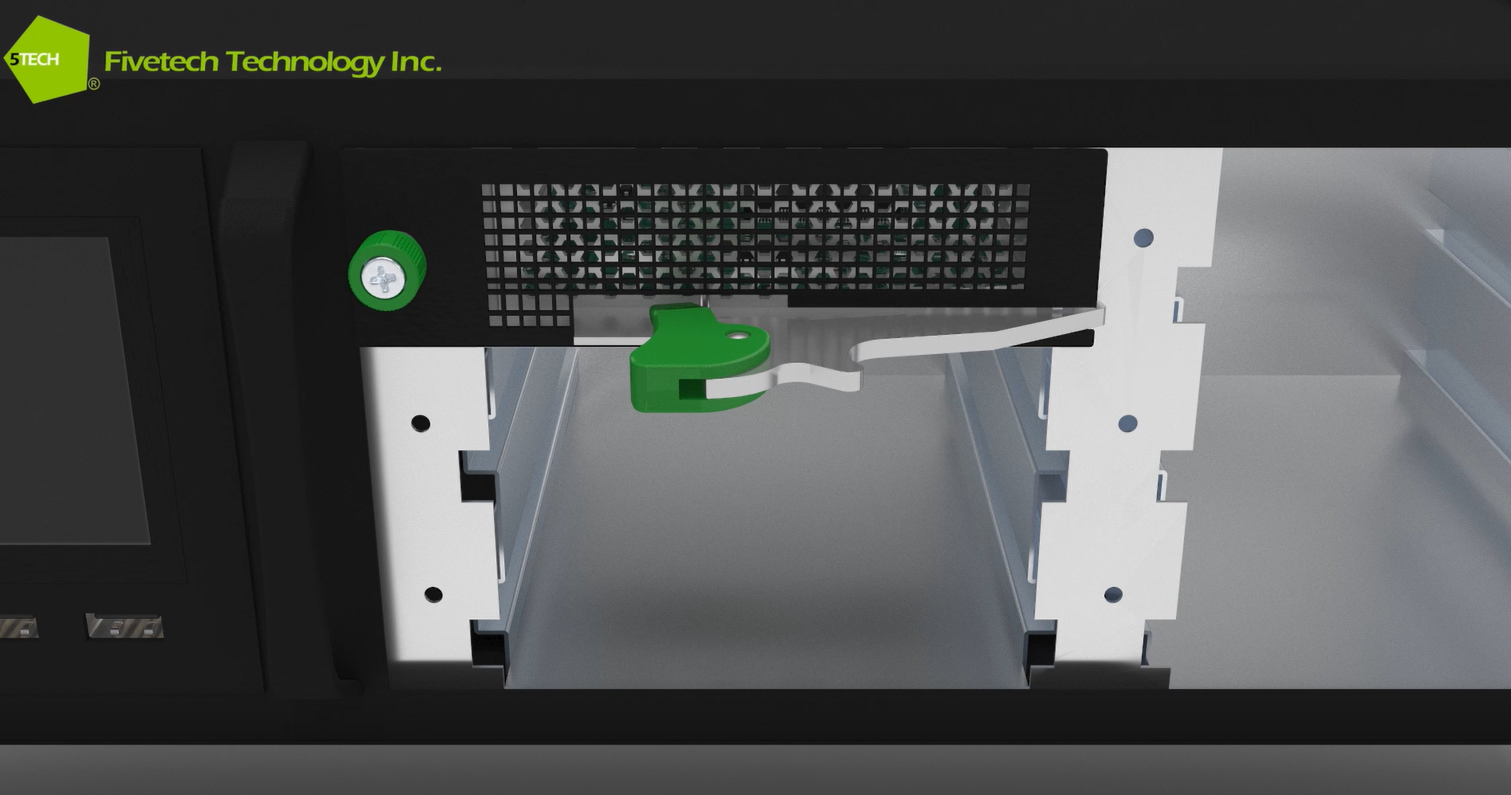

Rotating Ejector is the most complicated and frequently used set of locking tools in server applications. It is the most convenient and labor-saving solution to optimize the work efficiency of engineers. The automatic safety locking function of the special olecranon wrench head of the rotating catapult has a built-in spring mechanism design, which can automatically spring lock the catapult to the server body after the mechanism retracts its position, and strengthen the anti-collision and anti-loosening safety lock protection mechanism. At the rotating end of the mechanism lever, the lever design is used to eject the body of the mechanism, and the built-in strong torsion spring design can increase the elastic ejection force of the rotating ejector, making the locking force more flexible, and the tool locking experience is more stylish, personalized and modern . The lever component can also achieve 90。. The angle of rotation is the most ergonomically simple and intuitive operation of a set of rotating catapults when ejecting the server tray.

Rotating Ejector has a special automatic safety lock function. The olecranon wrench head is designed with a built-in spring mechanism design, which can automatically spring lock the catapult to the server body after the mechanism retracts its position, and strengthen the anti-collision and anti-loosening safety lock protection mechanism. The unique automatic safety lock function of the rotating catapult is beneficial to the stability of the server tray and prevents the tray from falling or falling off during movement and vibration. At the rotating end of the mechanism, the lever design is used to push out the body of the mechanism, and the built-in strong torsion spring design can increase the elastic ejection force of the rotating catapult, making the locking force more flexible, and the tool locking experience is more stylish, personalized and modern. Its unique flexible lever design helps to pop out of the server chassis, thereby saving engineers' workload and time during data center maintenance. Rotating Ejector has a compact and convenient design, which is very suitable for the limited space of the servo chassis cabinet. It is an ideal choice for any server above 1U, 2U, 4U. The plastic handle is heat-resistant, anti-static and anti-rust. The color of the handle can be customized according to the company ID color.

With lateral wheel trackSlide Roller, the server tray is regarded as a freely sliding roller cart. As long as the lateral wheel track is installed on the side of the chassis, each servo cabinet can achieve the most efficient. The power and time required to pull each layer of the server tray often results in a large waste of energy in the data center. If the key parts of the side wheel can be efficiently installed on the side of the server tray, it is like a freely sliding roller car the servo cabinet can easily slide forward and backward on the side rails, and the servo cabinet can be the most efficient energy saving system. Fivetech Slide Roller replace the general concave track with a roller track, and change the servo rack design by adding sliding rollers on the side. The wheel design can reduce the pulling force to improve the performance of the server product, and ensure that the spatial connection between the server and the mechanical structure components is maximized in acceleration efficiency. The stainless steel material can be easily installed on the metal plate by punching in, and the number of installed rollers can be adjusted and calculated according to the actual tray.

Slide Roller product features:

Strong load capacity.

The number of wheels used can be flexibly selected according to the load demand, and can be customized for development.

One-way Press-in connection is fast; save space; save cost.

Can do low-profile or Micro design planning.

Smooth and stylish rotation movement.

Fast drawing and rolling design with high wheel efficiency.

![]()