2015-01-29

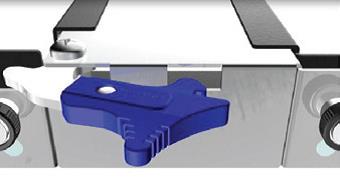

Faceplate hardware – Ejector Handle - ergonomic lever mechanism is design to engage least effort, least space, easy to operate function for frontboard faceplate, inject/eject server board from rack chassis carrier.

To settle the beset problem of lifting complex heavy board server/storage array in limited gap-space shelf, eject from rack/carrier/enclosure, Fivetech Ejector Handle on faceplate is design functional to solve this particular issue. Fivetech patented leverage configuration design can simply by press-down the plastic handle to leverage the heavy object, easy to operate to finely process inject/eject board from the shelf. Ejector Handle can modify design to accommodate lever or plunger style switch. For panel thickness can also adjust to proper fit to install handle on the faceplate. Handle size and length can be custom-made.

Features:

- thumb press action, press down to lock/unlock

- characteristic single plastic handle design

- the usage of leverage structure can easily boost to lift and eject.

- embedded auto-spring rebound to lock/unlock

- plastic parts → corporate identity color, size, shape can tailor-made

- plastic material → heat/rust resistance. cost reduction for module tooling.

- plastic light material to reduce shipment cost.

- Ejector standard test to meet at least 250 inject/eject cycle

- RoHS compliant.

- Ejector Handle Industry Application : Storage, Server, IPC, Telecom, Datacenter.

![]()