2015-10-02

Fivetech SMT Stop-ring plug is to block solder tin paste reflow or inflow during SMT assembling process to prevent screw thread pollute or damage.

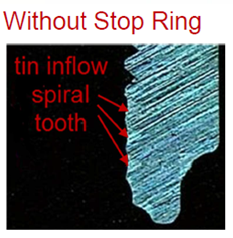

While SMT process refers to technique of melting tin as glue to stable mechanical parts on to faceplates, the extra liquid tin can easily back flow into the inner side of the standoffs/nuts causing serious damages and pollution. The inflow tin destroys the screw thread of the parts. It forms tin scraps, uneven thread spirals, tin bumps, and other flaws. It results in failure to thread in and solder splash due to forced screwing. The solder splash not only breaks the parts, but further splashes tin scraps onto PCB panels causing bigger mechanical problems. The possibility for short circuit is also high. The flaw badly increases the failure rate of products and increases rework costs. For worse, it lengthens the producing time due to reworks.

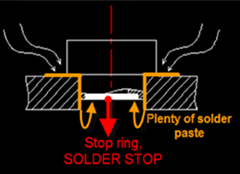

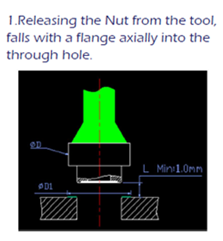

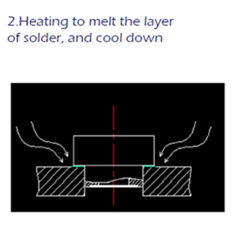

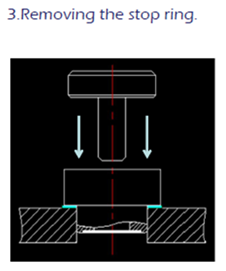

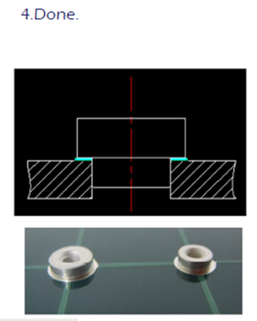

Solder Stop technique is the best method to solve this problem. Solder stop requires a stop ring which is mechanically placed into the bottom of a nut/ standoff. It matches the thread size seamlessly. When these parts are mechanically sealed onto faceplates using SMT, the stop ring prevents the liquid tin from inflowing into the thread hole. Hence, it keeps the screw thread perfectly intact. It then can be easily and effortlessly removed by a needle stick, leaving neither marks nor damages. Stop ring promises high soldering reliability, prevents ferrule inner structure and screw thread damaged by inflow of tine that may result in float volume reduction or solder paste existed between PCB and outer ferrule flow into inner side that may occur unstable reliability or other concerns.

With the application of solder stop, defected nuts/standoffs evidently declines. Eventually it optimizes product success rate. It saves costs, saves time and increases success rate. Solder Stop is obscure but its impact is significant. We strongly recommend Solder Stop to our customers for their benefits.

![]()