2015-09-24

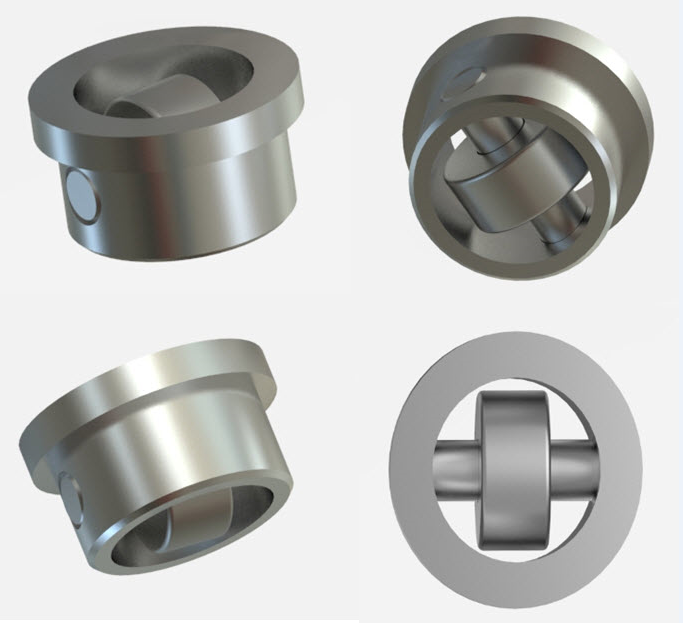

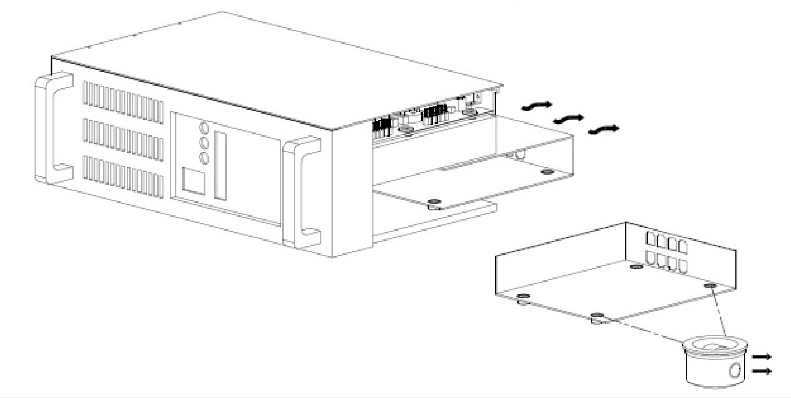

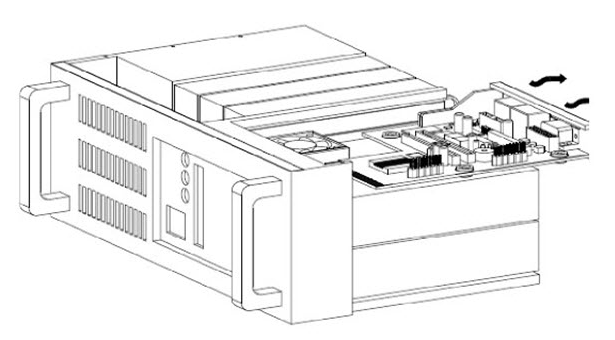

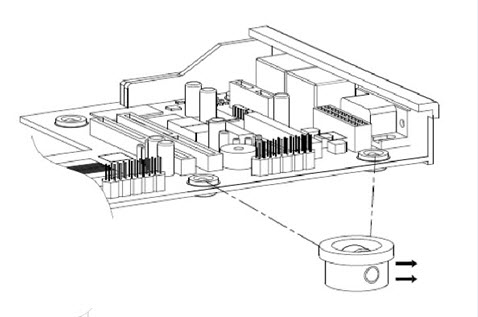

Fivetech groundbreaking new Roller series continues to realize Fivetech’s core value- speed, quality and reliability to offers diverse styles of product lines. Fivetech latest Wheel Roller presenting as twin product to Slide Roller, is designed to embed and install onto heavy server board to reduce repetitiously in-and-out drag force and share load-bearing so as to accelerate operation speed, rapid-repetitive mechanical, enhance performance.

Usually in data center full of racks installed hundreds of servers, those server board requires repeatedly pulled and pushed to maintain server functioning. During the operation could causing engineer much extreme strength and overloaded effort to keep data center functioning. Frictions of the heavy moving chasses could cause serious work-load for engineers during their maintenance. The new invention of wheel roller can strength and optimized mechanical part performance to its best benefits, save time and effort and eventually accelerate overall working efficiency.

The advantage of using rollers “wheel-on-board” can reduce noise but increase speed. Wheel Roller minimized friction possibility. Wheel Rollers can be easily added for better weight capacity. In addition, the wheel design prevents mechanism collision, allowing the product to maintain at its best condition.

Fivetech patented unique wheel roller has more advantage lies in design. The concept of wheel roller is to add rollers onto panels. It is entirely customized and reliable. Simple “wheels on board” design can benefits in operation function. Wheel Roller can flexibly match different mechanisms according to customer’s distinctive server board design. We expect Fivetech Roller series will become the newest industrial best advantage for server products.

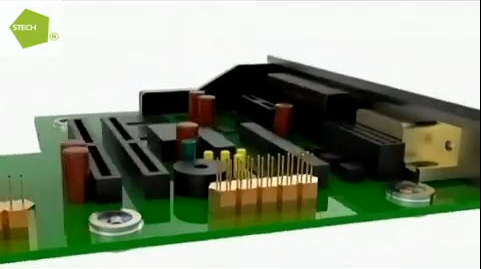

Wheel roller acts on multiple functional styles, maximized product quality and reliable in weight capacity mechanism. Wheel Roller offers two types of installation methods: Press in Self-clinching installation style, recommend to use on metal board; SMT type-SMT installation is recommend to use on server MB/PCB. Wheel roller offers customized specification according to customer’s distinctive server board design.

![]()