2018-03-23

Fivetech Ball Roller design purposes to speed up the pulling speed of an overweight server storage chassis, to reduce the gravity friction, adds extra ball roll-function to boost the sliding drawer which to solve the overload problem due to its excessive load, furthermore to enhance its upmost work efficiency.

Usually in cloud data center full of hundreds racks of servers storages, those server board requires repeatedly pulled and pushed to maintain its functioning. During the operation could causing engineer much extreme strength and overloaded effort to keep running. Frictions of the heavy moving chassis could cause heavy work-load for engineers during maintenance. The new invention of ball roller can strength and optimized mechanical part performance to its best benefits, save time and effort and eventually accelerate overall working efficiency.

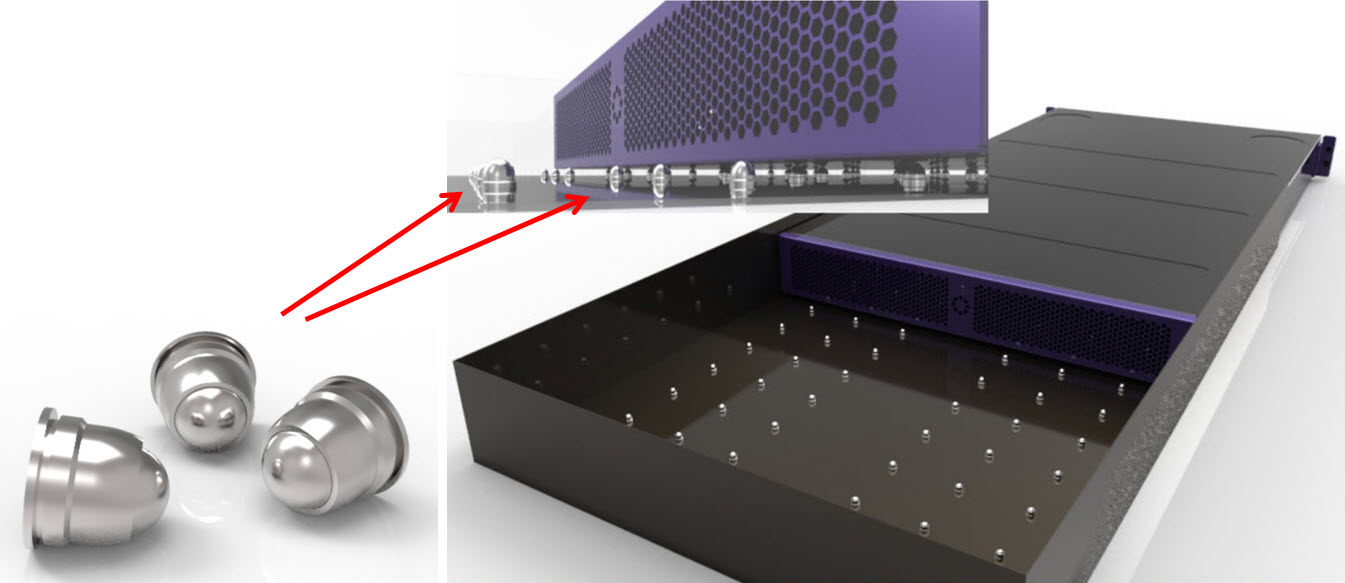

Fivetech Ball Roller is specialized for accelerating the pulling speed of an overweight server/storage chassis. Ball rollers ranged displayed and deployed installed arrayed on the inside plate of chassis, purposes to speed up the pulling speed, to reduce the chassis gravity friction, add extra roll-function to boost sliding chassis, which can solve the server chassis overweight problem due to its excessive load, furthermore to enhance its work efficiency. It’s designed to reduce effort and release weight of each time moving the heavy server chassis from shelf, to embed ball rollers onto heavy chassis plate to reduce repetitiously in and out drag force. The advantage of using ball rollers can reduce noise but increase speed. Ball Roller minimized friction possibility. In addition, the ball roller design prevents mechanism collision, allowing the product to maintain at its best condition.

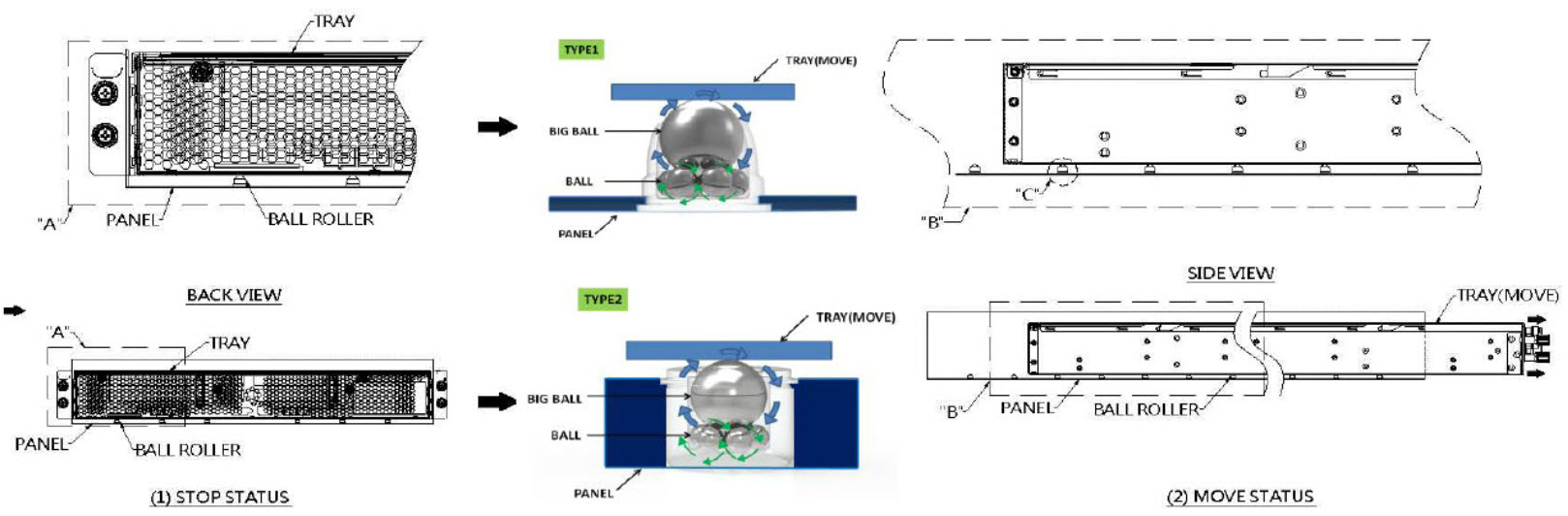

Ball Roller's design core is that the top larger ball and small balls spheres rotate on each other inside the ball roller to drive the action. This high-precision ball roll design has driven the component assembly technology into another threshold, driving new demanding for server storage equipment design in addition to the existing product functional requirements, into developing another product trend to focus on improving the overall hand operation efficiency of the hardware equipment. This product design provides high-precision ball transmission concepts can be applied in any industry applications that needs to speed up and accelerate the machine operation.

The Ball Roller is deployed on the inner panel of the chassis, it forms a display of rollers between the chassis and the drawer. The ball rollers can rotate 360 degrees with no certain directionality. Its free roll function can avoid the direction restrictive navigation, or it may cause direction deviation by the long-term rapid uses of operation. Roller designed to reduce noise and friction surface, can easily adjusts and positioned .

Ball roller has two types of layouts: upper assembly / face down assembly. It can be used for various drawer angles. Ball displayed size and numbers can be customized according to product requirements. Fivetech Roller series continues to realize Fivetech’s core value- speed, quality and reliability to offers diverse styles of product lines. Latest Ball Roller presenting as twin product to other roller series, shares load-bearing so as to accelerate operation speed, rapid-repetitive mechanical, enhance performance.

Fivetech patented unique ball roller has more advantage lies in its design. The concept of ball roller is to add balls onto panels. It is entirely customized and reliable. Ball Roller can flexibly match different mechanisms according to customer’s distinctive server board design. We expect Fivetech Roller series will become the newest industrial best advantage for server products.

Youtube Video

![]()