2018-05-07

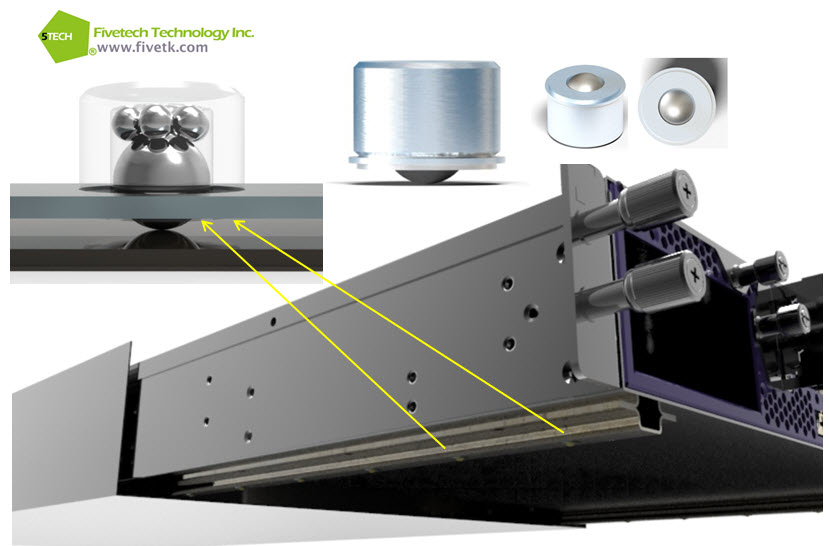

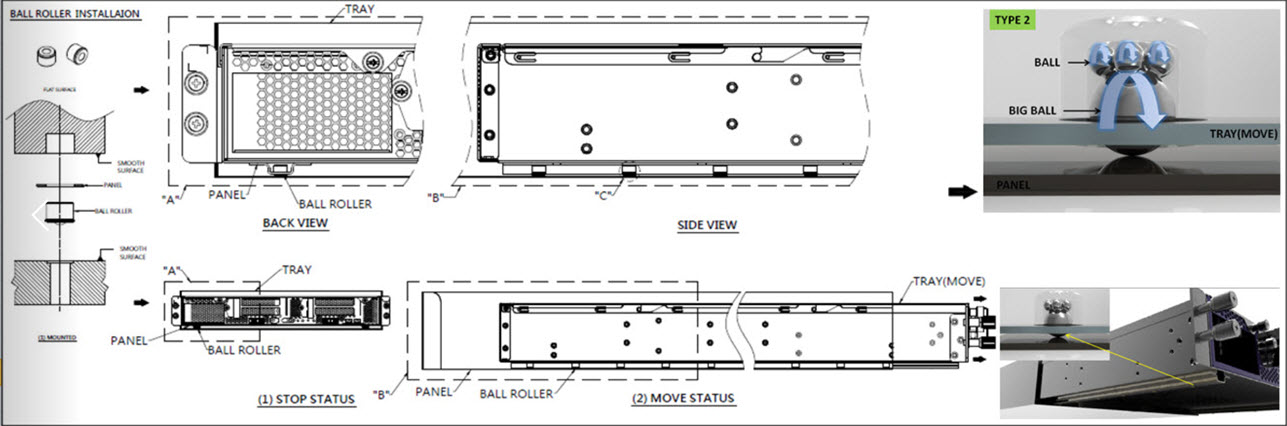

Fivetech Ball Roller Type II – below board low profile type is specialized in for server chassis that only provide a highly limited space underneath the server tray due to the restrictions of space; specially design for the chassis that can only installs rollers direction downwards at the bottom of server tray.

To converse assembly direction to Ball Roller Type I, Ball Roller Type II - below board low profile type is a reverse mounting device roller product for space highly restrictive in height. In view of the server design trend towards to be slighter and compactness, more space-saving and more energy-efficient; for additional value-added component parts shall also designed trend towards micromodule. Without interferes the original chassis design, in addition to the convenient use of the tool accessories that originally used the manual operation function, how to attach multi-function accessory parts to the chassis to make it easier and faster to save time and energy is also an additional consideration that must be taken into when designing the new gen server product to be advantaged.

Ball Roller Type II can be fixed in points, straight lines, or plane arranged in the bottom of the server tray mount into the panel, the ball protrudes from below under the iron plate, becomes wheel-like slide at the bottom of the tray, this function can increase the speed of the tray sliding, reduce the weight resistance, and allow users to easily and quickly pull. Standard Ball Roller type II can bear a minimum load capacity of 5kgf, if need more weight required, it can be freely specifications to meet the customer's product design constraints.

Usually in cloud data center full of hundreds racks of servers storages, those server board requires repeatedly pulled and pushed to maintain its functioning. During the operation could causing engineer much extreme strength and overloaded effort to keep running. Frictions of the heavy moving chassis could cause heavy work-load for engineers during maintenance. The new invention of ball roller can strength and optimized mechanical part performance to its best benefits, save time and effort and eventually accelerate overall working efficiency Fivetech Ball Roller series is specialized for accelerating the pulling speed of an overweight server/storage chassis.

Ball Roller Type II is differ than type I, its core design is the top smaller balls and below larger ball interact each other, sphere rotate on each other inside the ball roller to drive the movement. This high-precision ball roll design has driven the component assembly technology into another threshold, driving new demanding for server storage equipment design in addition to the existing product functional requirements, into developing another product trend to focus on improving the overall product efficiency of hardware equipment. This product design provides high-precision ball transmission concepts can be applied in any industry applications that needs to speed up and accelerate the machine operation.

Ball Roller type II are deployed at the bottom of server tray, it forms a display of rollers between the chassis box and the drawer tray. The ball rollers are universal directional free roll can avoid the direction restrictive navigation, or it may cause direction deviation by the long-term rapid uses of operation. Roller designed to reduce noise and friction surface, can easily adjusts and positioned base on the server design. Fivetech Ball Roller series has two types of layouts for various drawer angles.

Youtube Video

![]()