2020-05-11

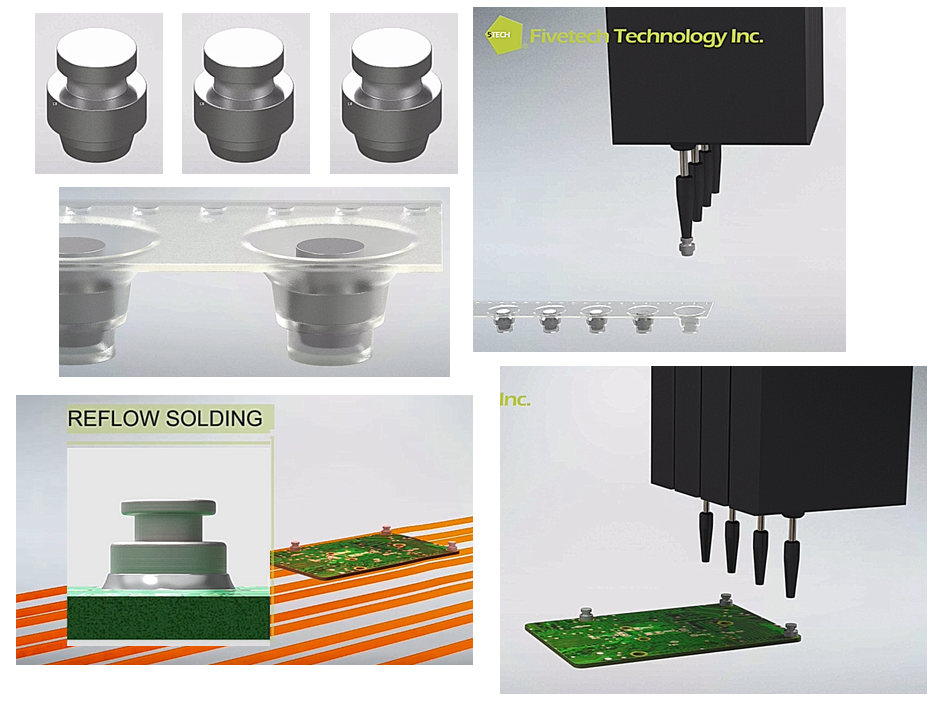

Fivetech SMT SPOOL are fully automatic SMT welding assembly, quick disassembly and assembly without using general screws, high-strength soldering welding combined force, low profile, micro miniaturization, suitable for mobile phones / notebooks / server / Networking/Telecom / Industrial Computer / Cloud / TV / Monitor ...

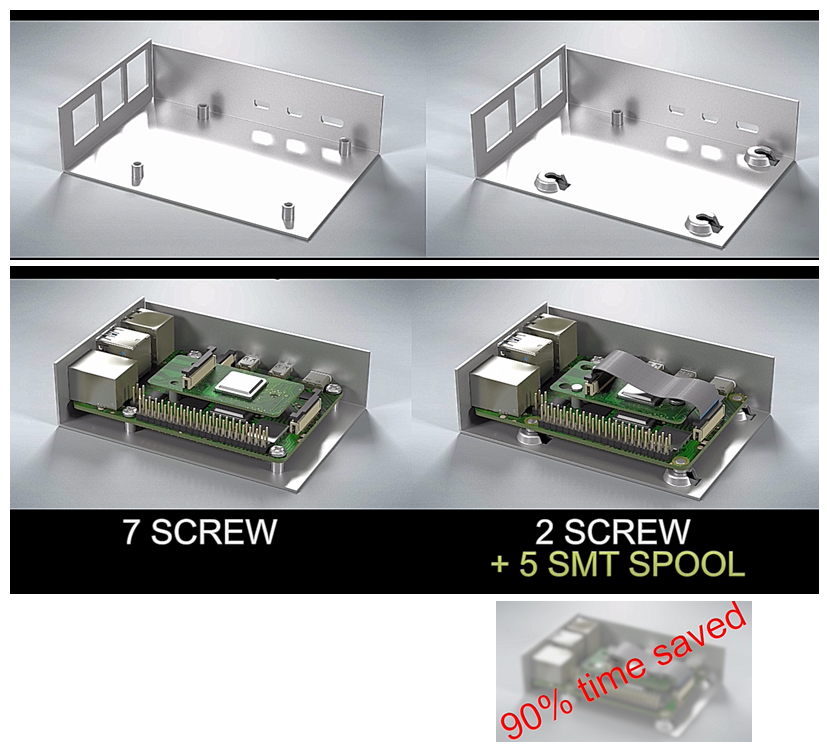

Save 90% assembly time compared with traditional screws

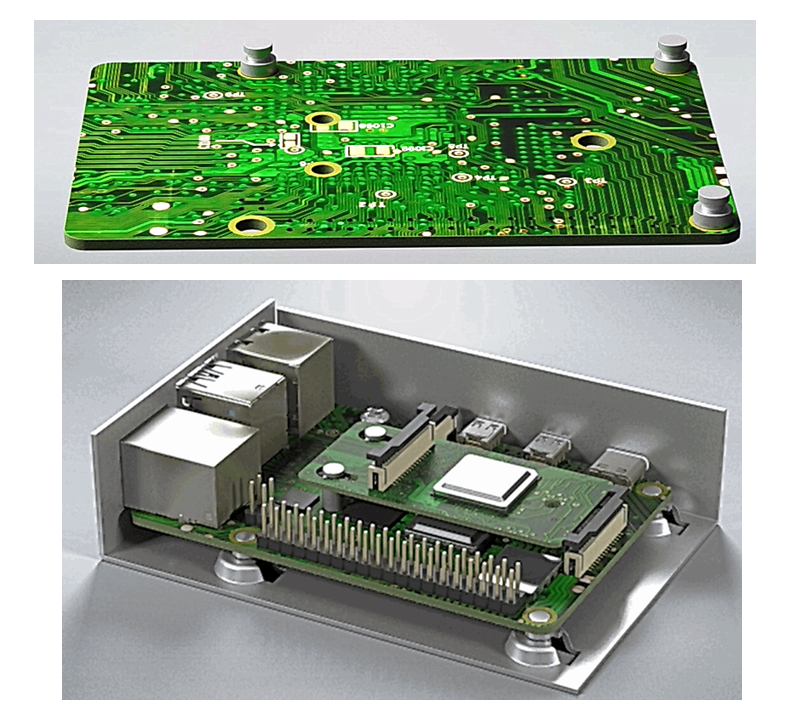

Fivetech SMT SPOOL are specially designed to assemble the sub-card quickly and easily to the server motherboard, quickly reconnect or disassemble, and the sub card can be locked in seconds. Just slide the sub card through the gourd-shaped hole to quickly connect or remove , and slide left and right to the horizontal locking direction.

Due to the application requirements of the server motherboard, various types of sub cards are usually required. The installation of most sub cards requires traditional screws that cannot be quickly removed and replaced. SMT SPOOL can be bent at different heights and can be between boards and boards Used as a high plate gasket. Low profile and micro miniaturization; SMT surface mount technology refers to the surface mounting technology that melts tin into tin glue until it cools and stabilizes the SMT studs on the PCB panel. SMT spool provide different functions and installation designs; micro miniature low profile can be used for mobile phones / notebooks / server / Networking/Telecom /industrial computers / clouds / TV / monitors ..... SMT engineering the high-profile shims can be used as four-post shims on slot servers; customers often use SMT spool+ fixing screws on server boards, which can emphasize the convenience of card installation and the characteristics of easy replacement.

When the safe assembly method is so complicated, SMT spool are really flexible when engineers move the chassis and replace cards. The design body has the purpose of easy assembly and quick release. Since threaded connections are disabled, simply place the sub board down through the larger hole of the hoist hole, and then slide the second board to the horizontal locking direction to insert the panel into the smaller hole. It is fixed in the second position as tightly as other fasteners. It expands the range of product applications. You can also press it into the side of the chassis or panel to fix the panel or panel on the side of the chassis. It not only saves ground space, but also makes full use of three-dimensional space. SMT spool are used in chassis with limited space on motherboards that cannot be driven vertically. The horizontal locking system saves execution space. It saves operation time and provides the simplest fastening method.

Save 90% assembly time compared with traditional screws

![]()